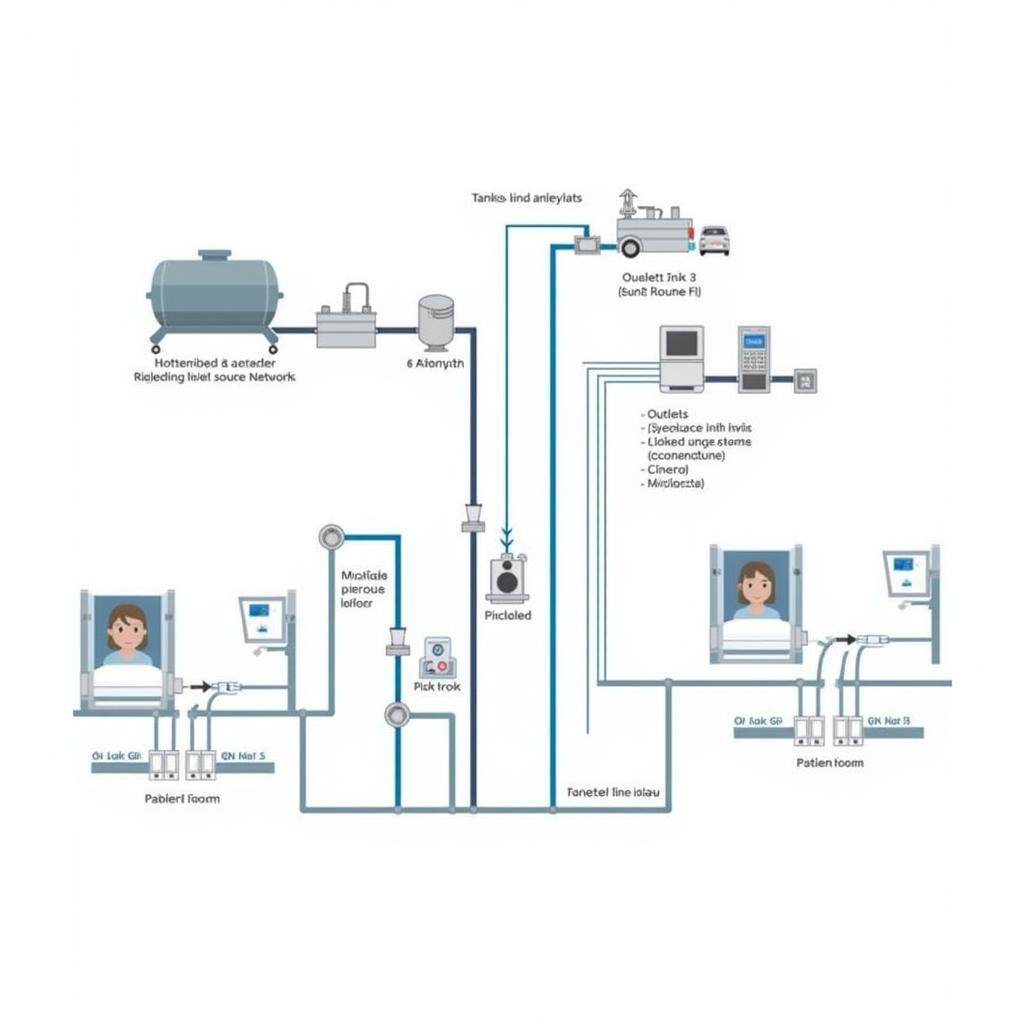

A medical gas pipeline system is a crucial component of any modern hospital, ensuring the safe and reliable delivery of medical gases to patients. These systems are intricate networks of pipes, outlets, and control valves that transport essential gases like oxygen, nitrous oxide, and medical air to various parts of the hospital grid. This infrastructure plays a vital role in supporting patient care across numerous departments, from operating rooms to intensive care units.

Understanding the Importance of a Robust Medical Gas Pipeline System

Effective delivery of medical gases is paramount for patient safety and positive health outcomes. A well-designed medical gas pipeline system minimizes the risks associated with handling and transporting gas cylinders, creating a safer environment for both patients and staff. It also streamlines operations by ensuring a constant and readily available supply of medical gases, eliminating the need for frequent cylinder replacements. This efficiency is especially crucial in critical care settings where immediate access to medical gases can be life-saving. Imagine a busy operating room – a continuous, reliable gas supply is non-negotiable.

The implementation of a hospital grid plays a significant role in optimizing resource allocation within the medical facility.

Key Components of a Medical Gas Pipeline System

A typical medical gas pipeline system comprises several key elements working in tandem. These include:

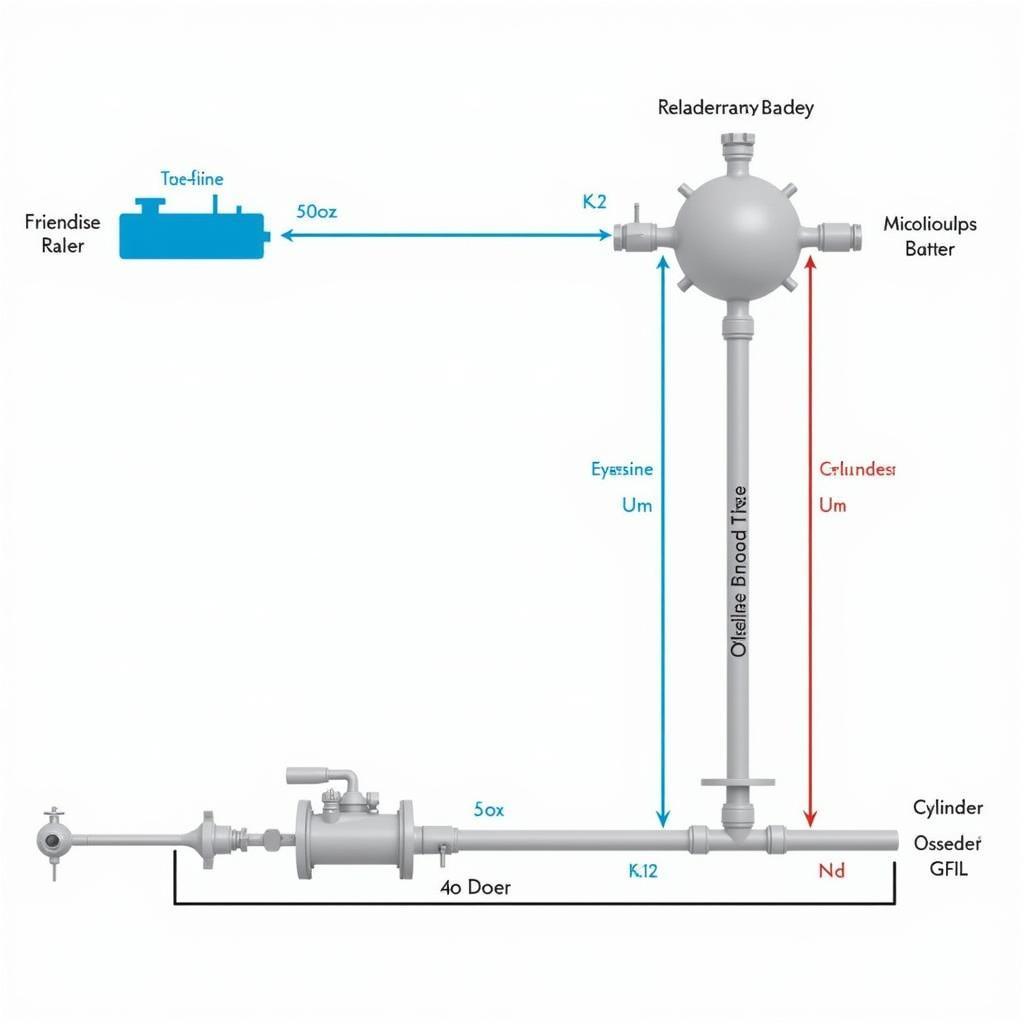

- Source Equipment: This includes bulk storage tanks, manifolds, and control systems that regulate the flow and pressure of gases entering the pipeline.

- Pipeline Network: A network of pipes, typically made of copper or stainless steel, carries the gases throughout the facility.

- Outlets: Strategically placed outlets in patient rooms, operating rooms, and other areas provide access to the gases.

- Alarms and Monitoring Systems: Sophisticated monitoring systems continuously track gas pressure, flow rates, and purity levels, triggering alarms in case of any deviations.

- Safety Devices: Non-return valves, pressure relief valves, and other safety mechanisms prevent backflow, overpressure, and other potential hazards.

Medical Gas Pipeline System Key Components

Medical Gas Pipeline System Key Components

Ensuring Safety and Compliance with Medical Gas Pipeline Systems

Safety is paramount when it comes to medical gas pipeline systems. Regular maintenance, inspections, and testing are crucial to ensure the system’s integrity and prevent leaks, contamination, or other issues. Hospitals must adhere to stringent regulations and standards for medical gas systems, including those set by organizations like the National Fire Protection Association (NFPA) and the American Society of Mechanical Engineers (ASME). These standards dictate design specifications, installation procedures, and maintenance protocols to guarantee patient safety.

The hospital grid ensures that these critical systems are integrated seamlessly within the hospital’s infrastructure.

Benefits of a Modern Medical Gas Pipeline System

Modern medical gas pipeline systems offer several advantages over traditional cylinder-based systems:

- Enhanced Safety: Reduced risk of gas leaks and explosions.

- Improved Efficiency: Eliminates the need for manual cylinder handling and replacement.

- Cost Savings: Reduces long-term operational costs associated with cylinder procurement and logistics.

- Space Optimization: Frees up valuable storage space previously occupied by gas cylinders.

- Centralized Control: Allows for easier monitoring and management of gas supply.

Benefits of Modern Medical Gas Pipeline System

Benefits of Modern Medical Gas Pipeline System

How Does a Medical Gas Pipeline System Work?

The system begins with a central supply source, which can be either bulk storage tanks or manifolds connected to an external supplier. Gases are then distributed through a network of pipes to designated outlets throughout the facility. These outlets are equipped with quick-connect fittings that allow medical professionals to easily connect equipment such as ventilators and anesthesia machines. The entire system is constantly monitored for pressure and flow, ensuring a reliable and safe supply of medical gases. Think of it as the circulatory system of a hospital, delivering vital gases where they’re needed most.

Why is Regular Maintenance Important?

Regular maintenance is essential for ensuring the long-term reliability and safety of a medical gas pipeline system. Inspections should be conducted regularly to identify potential issues such as leaks, corrosion, and malfunctioning components. Routine testing ensures that the system meets all safety standards and regulations. Just like a car needs regular servicing to run smoothly, a medical gas pipeline system requires ongoing maintenance to perform optimally.

Medical Gas Pipeline System Maintenance

Medical Gas Pipeline System Maintenance

The hospital grid facilitates the maintenance and management of these essential systems.

Conclusion: Investing in a Reliable Medical Gas Pipeline System

Investing in a robust and well-maintained medical gas pipeline system is a critical decision for any hospital. It ensures patient safety, enhances operational efficiency, and ultimately contributes to better patient outcomes. By adhering to industry standards and implementing regular maintenance protocols, hospitals can ensure the reliable and safe delivery of medical gases for years to come. This investment in a medical gas pipeline system is a commitment to providing the highest quality of care.

FAQ

- What types of gases are typically delivered through a medical gas pipeline system? Oxygen, nitrous oxide, medical air, and vacuum are commonly delivered.

- How often should a medical gas pipeline system be inspected? Regular inspections and testing are crucial, and the frequency depends on specific regulations and hospital protocols.

- What are the key safety features of a medical gas pipeline system? Alarms, monitoring systems, non-return valves, and pressure relief valves are crucial safety components.

- What materials are used for medical gas pipelines? Copper and stainless steel are commonly used due to their durability and resistance to corrosion.

- What are the benefits of using a pipeline system over gas cylinders? Pipeline systems offer enhanced safety, improved efficiency, cost savings, and space optimization.

- How is the purity of medical gases maintained in a pipeline system? Regular testing and purification processes ensure gas purity adheres to stringent standards.

- Who is responsible for the maintenance of a medical gas pipeline system? Trained and certified technicians are responsible for maintaining these systems.

Need help with your hospital infrastructure? Contact us! Phone: 02437655121, Email: [email protected]. Visit us at: No. 298 Cau Dien Street, Minh Khai, Bac Tu Liem, Hanoi, Vietnam. We have a 24/7 customer service team.